- INVpack

- 09/09/2025

- 09:39

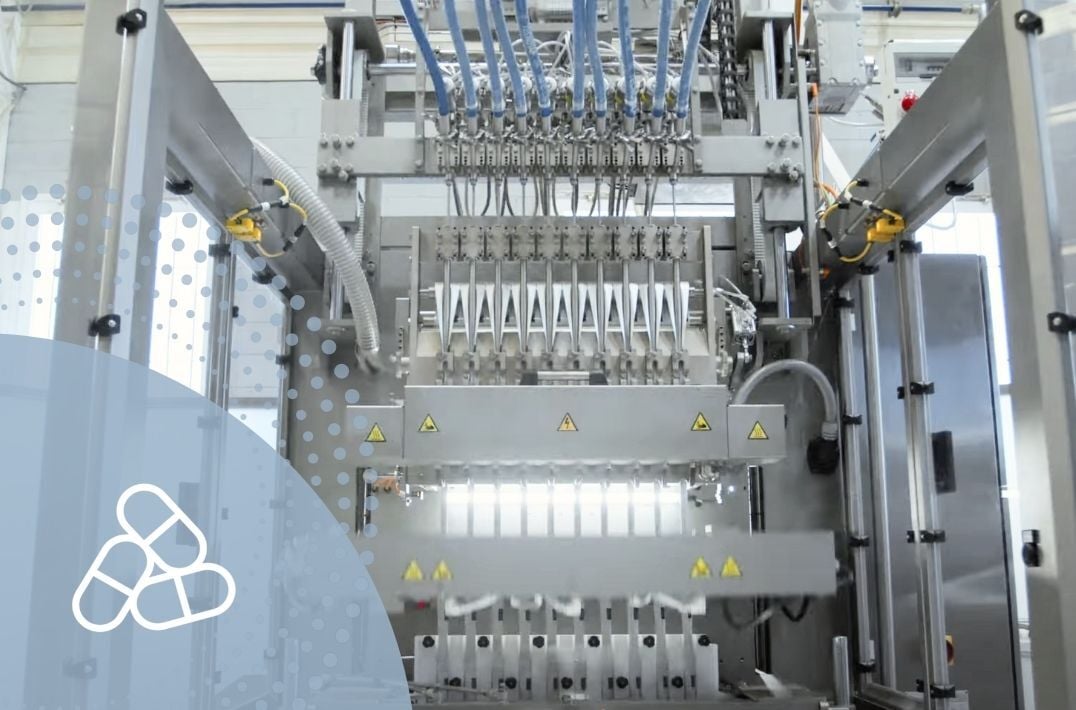

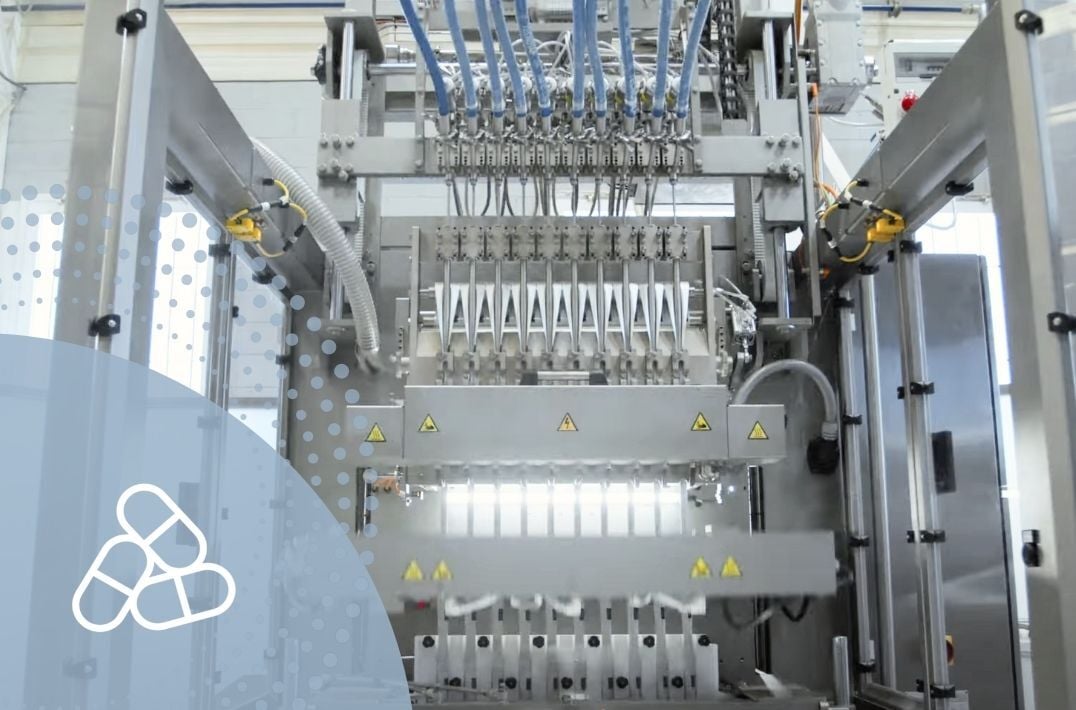

How Vertical Packaging Machine Manufacturers help reduce operational costs in Pharma

Pharmaceutical companies worldwide face constant challenges: high production volumes, rising operational costs, and the need to comply with strict regulatory requirements.

In this context, vertical packaging machine manufacturers play a critical role by delivering advanced solutions that enhance efficiency, reduce waste, and ensure compliance across production lines.

Vertical packaging machine manufacturers and cost efficiency in pharma

The connection between packaging machine manufacturers and cost savings in pharma is direct and measurable. By integrating high-precision dosing systems, vertical packaging equipment minimizes raw material waste, reduces labor dependency, and optimizes packaging material usage. These improvements drive leaner operations, optimized batch production, and stronger financial performance.

Reducing product waste through accurate dosing

Active pharmaceutical ingredients (APIs) and excipients are expensive, and even minor deviations in dosing can result in significant financial losses. Pharma-grade vertical packaging machines guarantee accurate dosing and consistent sealing, reducing waste while maintaining GMP compliance. This accuracy preserves valuable resources and ensures that each packaged unit meets the highest quality standards.

Choosing the right vertical packaging machine partner

Not every machine, and not every manufacturer, delivers the same level of value. Selecting the right partner is essential for long-term cost savings. Beyond the initial investment, a reliable manufacturer provides ongoing benefits through robust support, regulatory expertise, and seamless integration with automation systems such as SCADA or MES.

Key features to look for in pharma-ready packaging machines

When evaluating suppliers, pharmaceutical companies should prioritize packaging machines that offer:

- Comprehensive audit trails to withstand regulatory inspections

- Multi-line configurations for higher throughput

- Quick format changeover to minimize downtime

- Validation and GMP documentation to streamline approvals

These capabilities confirm that the equipment is not only compliant but also cost-efficient in the long run.

Operational benefits beyond cost savings

The benefits of vertical packaging machines go beyond immediate savings. Their durability, reliability, and efficiency provide long-term ROI. By reducing downtime and increasing throughput, they help pharmaceutical manufacturers strengthen competitiveness in both domestic and international markets.

Training, support and spare parts availability

Comprehensive after-sales service is another key factor. Leading manufacturers provide training, technical support, and readily available spare parts, which reduce unplanned stoppages and keep maintenance costs under control. This ensures production schedules remain stable and predictable.

Partnering with the right vertical packaging machine manufacturers is more than an equipment purchase, it is a strategic decision. It empowers pharmaceutical companies to reduce operational costs, maintain regulatory compliance, and secure long-term efficiency and competitiveness in global markets.

Related posts:

How to optimise liquid stick pack machine performance for viscous products

Optimising a liquid stick pack machine for viscous products requires a deeper technical approach...

Traceability in the packaging of pharmaceutical products

Traceability in the packaging of pharmaceutical products is an essential component of the industry,...

INVpack will be an exhibitor at INTERPACK next May

Next May INVpack will be an exhibitor, one more edition, at the INTERPACK fair.It will attend at...