- INVpack

- 11/17/2023

- 04:28

Packaging solutions featuring microdosing precision

Precision is a critical factor across industries, with particular emphasis in pharmaceutical and nutritional sectors, where exact product dosages are crucial for consumer health and well-being.

Microdosing has emerged as a key trend in these markets, enabling precise administration of active ingredients in small quantities. In this article, we will delve into the importance of technology and its evolution in microdosing packaging solutions.

The importance of precision in the pharmaceutical and Nutritional sectors

The demand for precision in dosing pharmaceutical and nutritional products is undeniable. Administering inaccurate doses can have serious consequences for consumer health. Moreover, in a world increasingly focused on personalized treatments and supplements, the ability to provide precise microdoses is essential.

India, a growing market in the pharmaceutical and nutritional industry, has become a key point of interest for microdosing packaging solutions. The country hosts a growing population seeking personalized treatments and high-quality nutritional supplements. However, the industry faces challenges in the availability of specialized machinery capable of handling microdoses with precision.

Microdosing and cutting-edge isolator technology

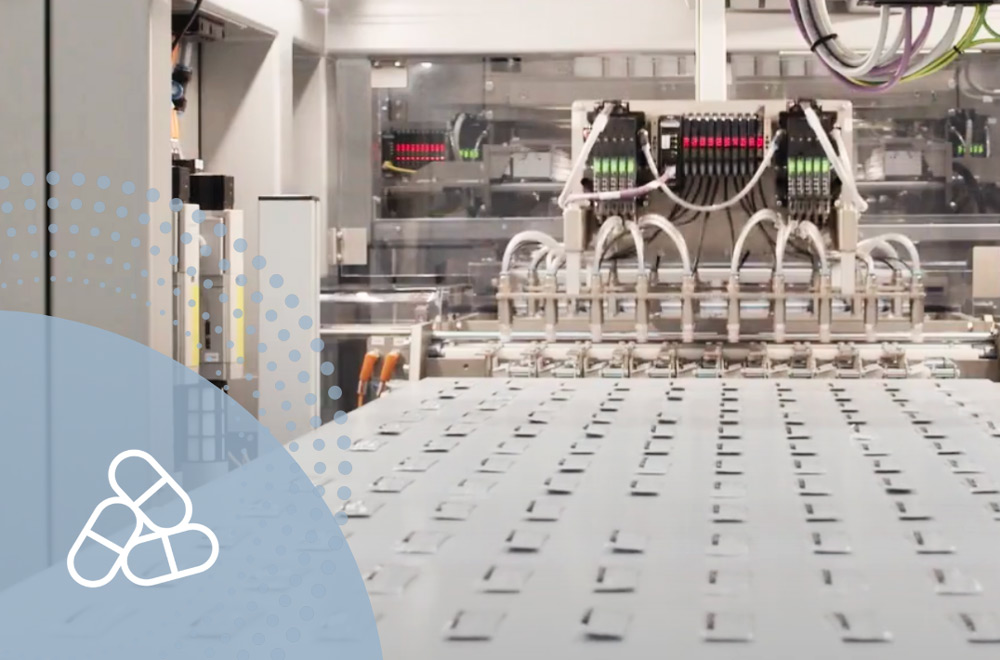

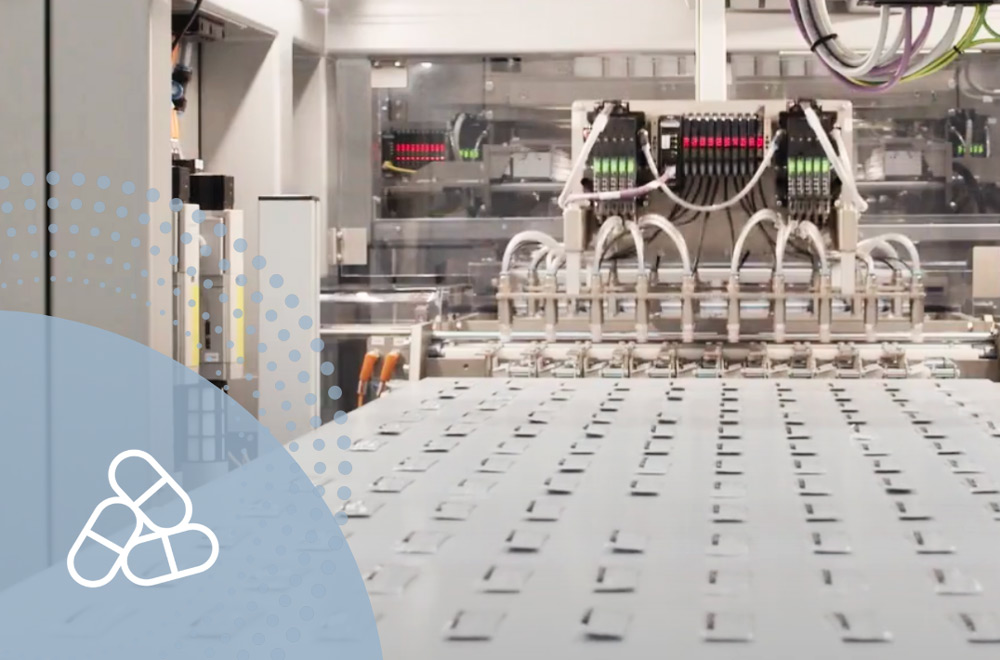

Microdosing involves the precise administration of very small amounts of active ingredients, often in the range of micrograms or milligrams. To achieve this precision, advanced technologies such as high-precision isolated cells are employed.

These cells enable the uniform and controlled dosing of ingredients, avoiding variability in the final dose. Isolated cells operate by separating small quantities of the main product, ensuring each dose is homogeneous and precise, offering an optimal microdosing packaging solution.

The benefits of this technology are evident: it ensures the safety and efficacy of pharmaceutical and nutritional products, minimizing the risks of overdosing or underdosing.

Competitive advantages of precise Microdosing

Precise microdosing provides several competitive advantages in pharmaceutical and nutritional sectors. Primarily, it guarantees the quality and efficacy of products, crucial for maintaining consumer trust and compliance with regulations. Additionally, by reducing the waste of active ingredients, production efficiency is improved.

Regulatory compliance is another strong point of precise microdosing. Companies adopting this technology can meet the strictest standards and demonstrate their commitment to consumer safety.

Microdosing Systems and INVpack Machinery

INVpack, a leading company in packaging solutions and a manufacturer of vertical packaging machinery, has developed and integrated systems that offer microdosing packaging solutions in its machines. This innovation allows pharmaceutical and nutritional companies to have cutting-edge machinery capable of administering microdoses with maximum precision.

Moreover, these systems align with current and future trends in microdosing, including automation and integration with Industry 4.0. Automation streamlines production and reduces costs, while integration with Industry 4.0 provides the ability to monitor and optimize processes in real time.

Precise microdosing is the key to excellence in the pharmaceutical and nutritional sectors. INVpack offers industry-leading packaging solutions incorporating this technology. If you want to learn more about how you can apply these solutions in your company or how they can benefit your production, feel free to contact us. Dosing precision is fundamental, and we are here to help you achieve it successfully.

https://www.invpack.com/

Related posts:

4 packaging trends in India and their impact on single-dose vertical packaging machinery

In the Indian packaging industry, trends are evolving rapidly to adapt to the demands of an...

INVpack - Experts in single dose packaging machines

INVpack is a vertical packaging machinery manufacturer created in 2003. In addition to its more...

INVpack, expert in micro-dosing for pharmaceutical packaging

INVpack is positioned as an outstanding leader in the field of flexible single-dose packaging,...