- INVpack

- 05/16/2025

- 08:45

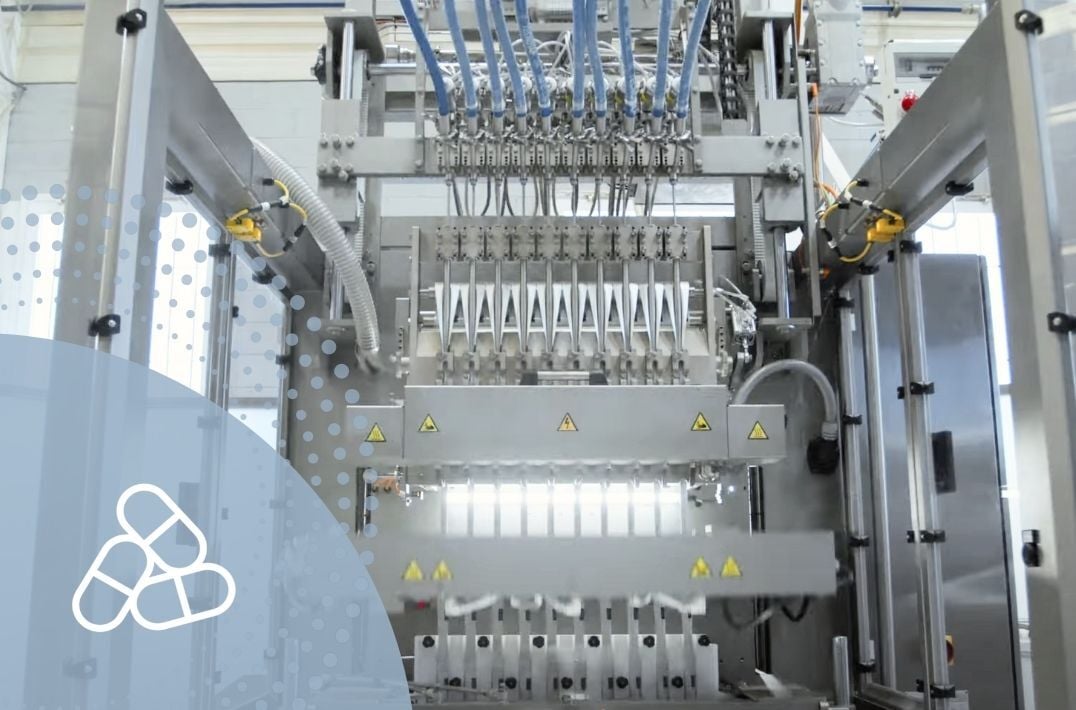

Pharmaceutical packaging lines: Optimisation and trends

Pharmaceutical packaging lines have evolved significantly in recent years, driven by the need to improve efficiency, safety and traceability in medicine production.

The evolution of pharmaceutical packaging lines: from automation to digitalisation

The transformation of pharmaceutical packaging has shifted from mechanical control to integration with advanced digital systems. This evolution has been driven by regulations that encourage innovation and continuous improvement. Digitalisation enables greater precision and control in packaging processes, reducing errors and boosting efficiency.

Optimising performance in pharmaceutical packaging lines

Strategies to maximise efficiency and minimise waste

To optimise performance, it is essential to implement strategies that reduce changeover times and minimise dosing and sealing errors. These include process automation and the use of advanced technologies that enable quick and accurate adjustments.

Real-time monitoring and predictive maintenance

The use of advanced sensors and IoT technologies in packaging equipment allows real-time monitoring and predictive maintenance. These tools help diagnose faults and perform data-driven maintenance, reducing downtime and enhancing operational efficiency.

Traceability and safety in pharmaceutical production

Serialisation and aggregation are fundamental in the fight against counterfeit medicines. Global regulations and compliance standards ensure traceability and safety in pharmaceutical production. In addition, advanced quality control systems such as vision inspection and defect detection algorithms ensure package integrity and sealing quality.

Flexibility and customisation in packaging lines

Adaptability to multiple formats is essential to meet market demands. Multi-lane machinery and rapid format change systems enable on-demand production and mass customisation, providing significant benefits in terms of efficiency and responsiveness.

Pharmaceutical packaging lines are constantly evolving, driven by digitalisation and the need for optimisation. Strategies to maximise efficiency, ensure traceability and provide flexibility are key to staying competitive in this sector.

Related posts:

Powder packaging machines, precision and quality in the food Industry

Packaging powder products in the food industry requires a high level of precision and quality to...

How Vertical Packaging Machine Manufacturers help reduce operational costs in Pharma

Pharmaceutical companies worldwide face constant challenges: high production volumes, rising...

Eco-friendly materials in Packaging gain popularity in India

The shift towards more sustainable packaging materials is gaining momentum in India, particularly...