- INVpack

- 07/05/2024

- 09:18

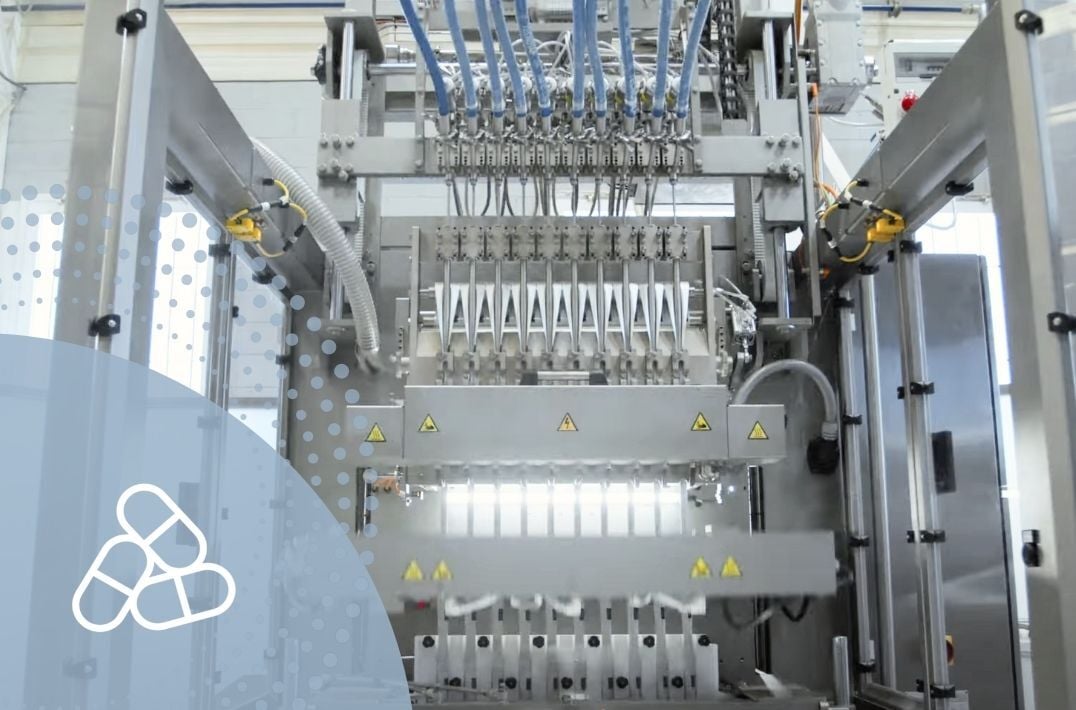

Enhance the accuracy and quality of your pharmaceuticals with multi-lane vertical packaging machines

In the pharmaceutical field, precision in medication packaging is crucial to ensure correct dosage and treatment efficacy. Multi-lane vertical packaging machines stand out as an advanced solution that guarantees a high level of accuracy, essential for maintaining the integrity and quality of the final product.

Technology of multi-lane vertical packaging machines for high precision

Multi-lane vertical packaging machines employ advanced technologies that ensure high precision in medicine packaging. These technologies include precise dosing systems and accurate sealing mechanisms. Unlike other types of packaging machines, multi-lane vertical packaging machines allow for more rigorous control and less variability in the amount of medication dispensed per unit, which is vital for medical treatments requiring exact doses.

Key components ensuring precision in medication packaging

The precision in multi-lane vertical packaging machines is achieved through specific components and mechanisms. The dosers are essential for ensuring the exact amount of medication in each package. Additionally, advanced functionalities such as sensors and automated control systems play a crucial role in continuously monitoring the packaging process. Integrated weighing systems enable real-time verification and adjustment of dosing, thus ensuring consistency in every produced unit.

Benefits of precision in final product quality

The relationship between precision in packaging and medication quality is direct and significant. Precise dosing reduces product variability, improving its consistency and effectiveness. For instance, in liquid or powder medications, high precision in packaging ensures that each dose contains the exact amount of active ingredient, which is crucial for treatment efficacy and patient safety.

Process optimization to maintain precision

Maintaining precision in packaging requires continuous process optimization. This includes regular machinery maintenance, frequent calibration of dosers and other key components, and the implementation of quality control strategies. Periodic adjustments and verification of the correct functioning of weighing systems and sensors are essential to ensure that precision is maintained throughout the production process.

Regulations and compliance related to packaging precision

Regulations in medication packaging demand a high level of precision to ensure product safety and efficacy. Standards such as Good Manufacturing Practices (GMP) establish strict criteria that multi-lane vertical packaging machines help meet. These machines are designed to fulfill regulatory requirements through their precise dosing capability and continuous process monitoring, thus ensuring the quality and consistency of the final product.

Final reflection on investing in multi-lane vertical packaging machines

Investing in multi-lane vertical packaging machines is a strategic decision for any pharmaceutical company aiming to guarantee the highest quality standards in its products. The precision offered by these machines not only enhances treatment efficacy and patient safety but also ensures regulatory compliance and reduces product variability. With the right technology, precise components, and rigorous maintenance, multi-lane vertical packaging machines become an indispensable tool for medication packaging.

In summary, multi-lane vertical packaging machines are essential for achieving precise dosing, improving final product quality, and meeting the strict regulations of the pharmaceutical sector. Ensuring medications are packaged with the necessary accuracy is a crucial step in guaranteeing effective and safe treatments.

Related posts:

INVpack, manufacturers of sachet packaging machinery

The single-dose sachet is one of the most common packaging in the world of flexible packaging. To...

How Vertical Packaging Machine Manufacturers help reduce operational costs in Pharma

Pharmaceutical companies worldwide face constant challenges: high production volumes, rising...

Sustainability: INVpack's commitment to the environment

The need for sustainable packaging solutions The environmental impact of plastic on our planet is a...