- INVpack

- 01/28/2026

- 09:15

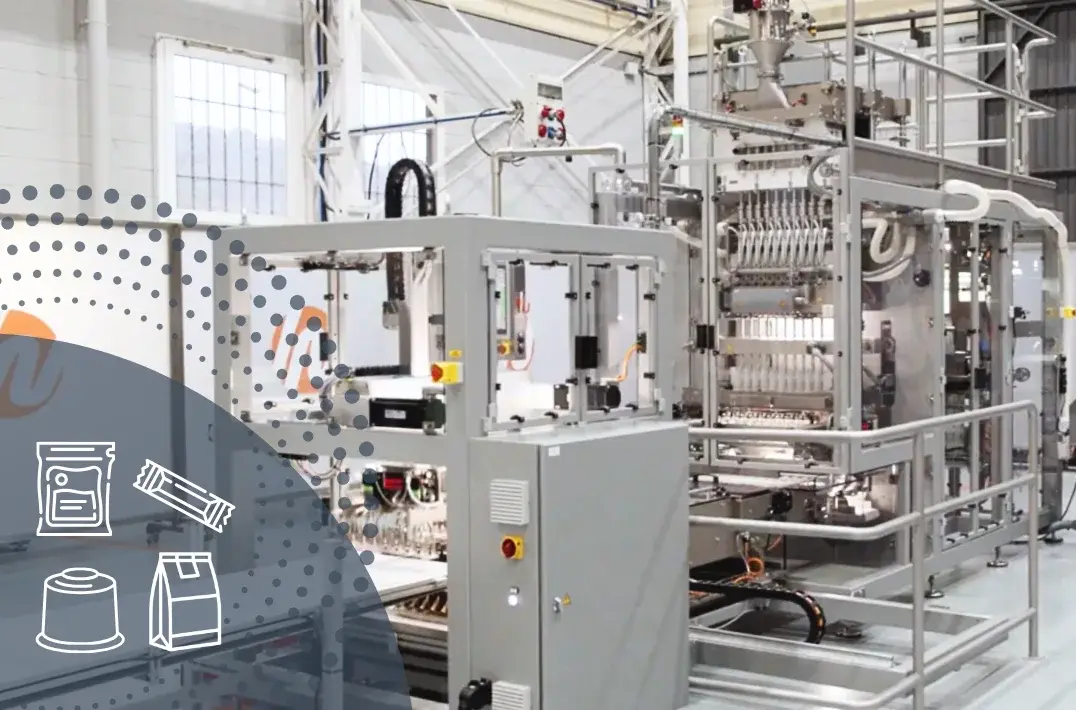

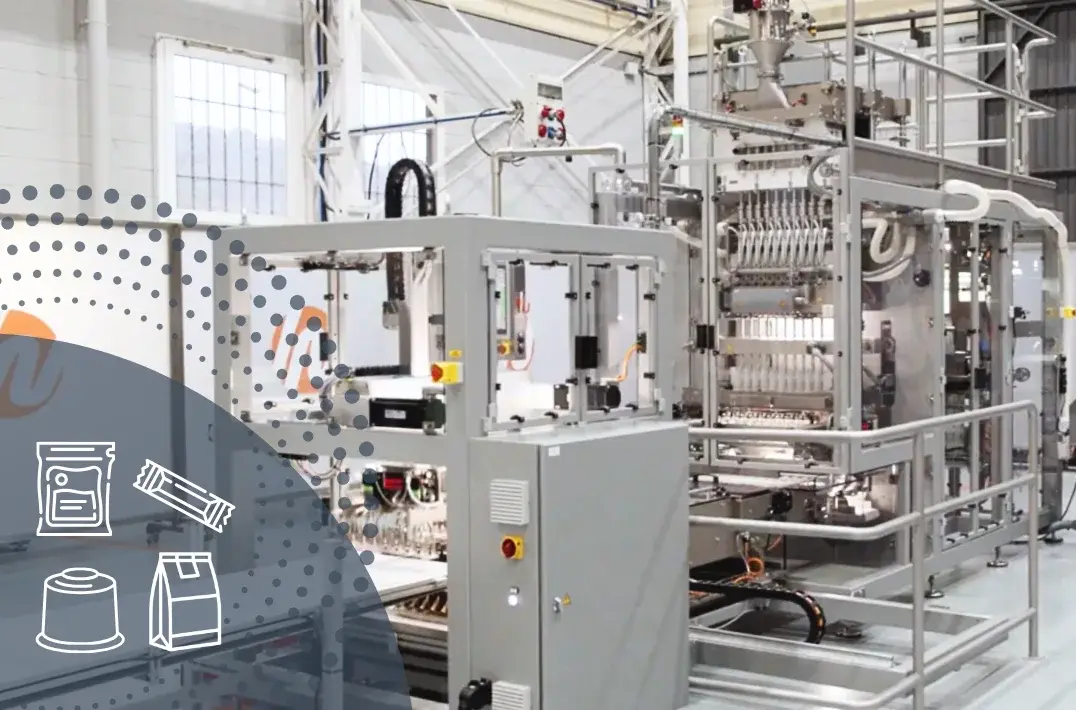

Industrial packaging machinery for medium-to-high output businesses

As production volumes increase, packaging operations must evolve in parallel. For medium to high output businesses, investing in industrial packaging machinery is often a necessary step to maintain efficiency, ensure process stability and support controlled growth.

Unlike entry level or semi automatic systems, industrial packaging machinery is designed for sustained operation, higher output rates and integration within automated production environments. In vertical and single dose applications, these systems must combine precision, repeatability and adaptability to different products and formats.

Understanding industrial packaging machinery

Within the vertical and monodose packaging sector, industrial packaging machinery refers to fully automatic systems capable of forming, filling and sealing flexible packaging materials at medium to high speeds.

From a functional perspective, industrial packaging machinery typically integrates:

- Forming units that shape the film into stick pack or sachet formats

- Filling systems adapted to powders, granules, liquids or viscous products

- Sealing and cutting stations that ensure pack integrity and dimensional consistency

Classification can also be made according to automation level. Industrial systems generally incorporate servo driven movements, programmable control platforms and in line monitoring systems to maintain stable production parameters over extended runs.

When to invest in industrial packaging machinery

The transition to industrial packaging machinery usually occurs when operational complexity exceeds the capacity of semi automatic or low speed equipment.

Common drivers include sustained growth in demand, the need to internalise outsourced packaging, expansion into new formats or markets, and increased traceability or regulatory requirements.

Signs your current setup is limiting growth

Certain operational indicators suggest that existing equipment is no longer adequate:

- Production bottlenecks caused by limited output capacity

- Inconsistent fill accuracy or seal quality

- High dependence on manual intervention

- Increasing cost per unit due to inefficiencies

- Limited ability to introduce new pack sizes or formats

When these factors begin to affect delivery performance or margins, industrial packaging machinery becomes a rational investment option rather than an expansion luxury.

ROI thresholds and scalability

Return on investment depends on production volume, operational efficiency gains and long term demand forecasts.

Industrial packaging machinery typically becomes economically viable when automation significantly reduces labour dependency, improves yield and increases throughput without proportionally increasing operating costs.

Scalability is also critical. The selected system should allow capacity adjustments, additional lanes or integration with complementary equipment, avoiding premature obsolescence.

Key features to look for in industrial packaging machinery

Selecting the right industrial packaging machinery requires evaluating both technical capabilities and long term operational impact.

Versatility and format adaptability

In dynamic markets, the ability to adapt quickly is essential. Industrial packaging machinery should support different pack dimensions, film structures and product types with controlled and repeatable changeover procedures.

Efficient format change reduces downtime and allows manufacturers to respond to evolving commercial demands without compromising line stability.

Automation and connectivity

Modern industrial packaging machinery incorporates advanced automation platforms that enable precise parameter control, alarm management and production data recording.

Integration with ERP or MES systems facilitates traceability, batch control and performance analysis. Real time monitoring contributes to better decision making and structured continuous improvement.

Maintenance and support efficiency

High output production environments require predictable maintenance strategies. Industrial packaging machinery should provide easy access to wear parts, clear diagnostic systems and compatibility with preventive maintenance plans.

Remote support capabilities and spare parts availability further reduce unplanned downtime and protect operational continuity.

Common challenges in scaling with industrial packaging machinery

Scaling production with industrial packaging machinery also presents challenges.

Companies may face limitations in available floor space, utilities or qualified personnel. Inadequate specification during the selection phase can lead to underdimensioned systems or insufficient flexibility for future product variations.

A structured evaluation process, including technical validation and realistic capacity planning, reduces implementation risks and improves long term performance.

How to choose the right partner for your packaging line

The performance of industrial packaging machinery depends not only on the equipment itself but also on the expertise of the supplier.

A reliable partner should demonstrate proven experience in vertical and single dose applications, strong engineering support and structured after sales service. Customisation capability, spare parts logistics and technical training are essential factors in ensuring sustained performance.

Selecting a partner with a long term approach helps align the machinery investment with broader production and growth strategies.

Balancing productivity, investment and long term growth

Investing in industrial packaging machinery is a strategic decision that balances productivity gains with capital expenditure.

For medium to high output businesses, the objective is not only to increase speed, but to establish a stable, scalable and controlled packaging process. When properly specified and integrated, industrial packaging machinery becomes a key asset in supporting operational efficiency and sustainable growth.

Related posts:

How to optimise liquid stick pack machine performance for viscous products

Optimising a liquid stick pack machine for viscous products requires a deeper technical approach...

Packaging of energy paste in stick packs: Technology against child malnutrition

Severe acute malnutrition is a sad reality for many children in the world, especially in...

INVpack will be an exhibitor at INTERPACK next May

Next May INVpack will be an exhibitor, one more edition, at the INTERPACK fair.It will attend at...