- INVpack

- 10/14/2022

- 09:45

Benefits of packaging sachets in vertical machines

The contemporary lifestyle has led users to a consumption based on day-to-day life and above all on a consumption focused on practicality.

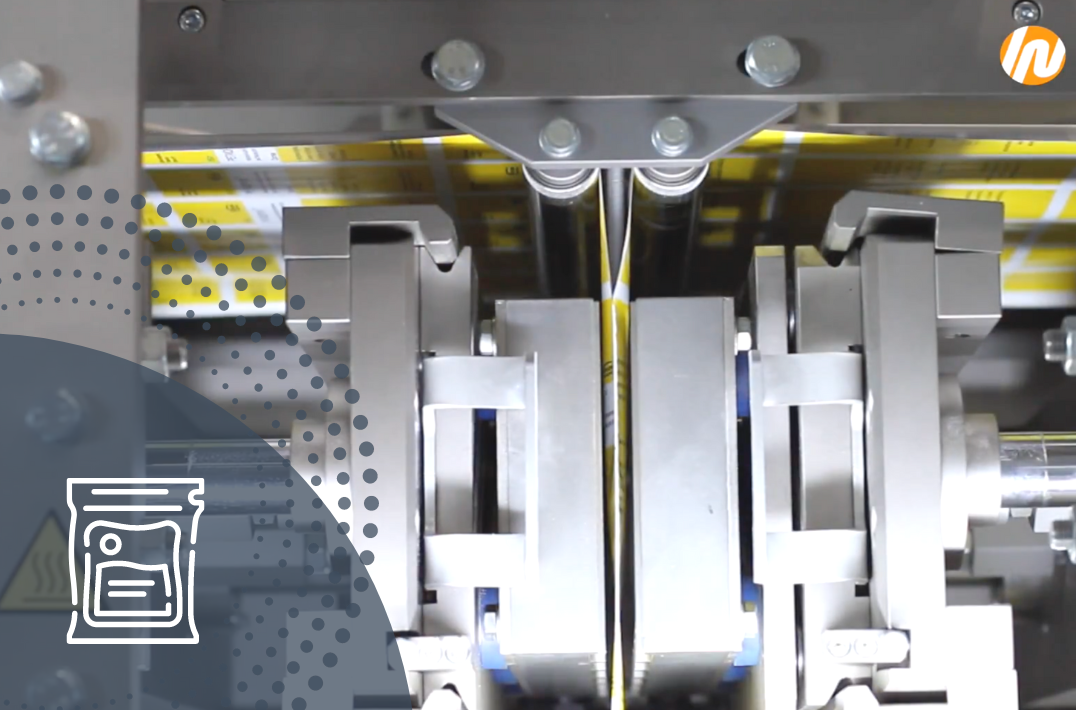

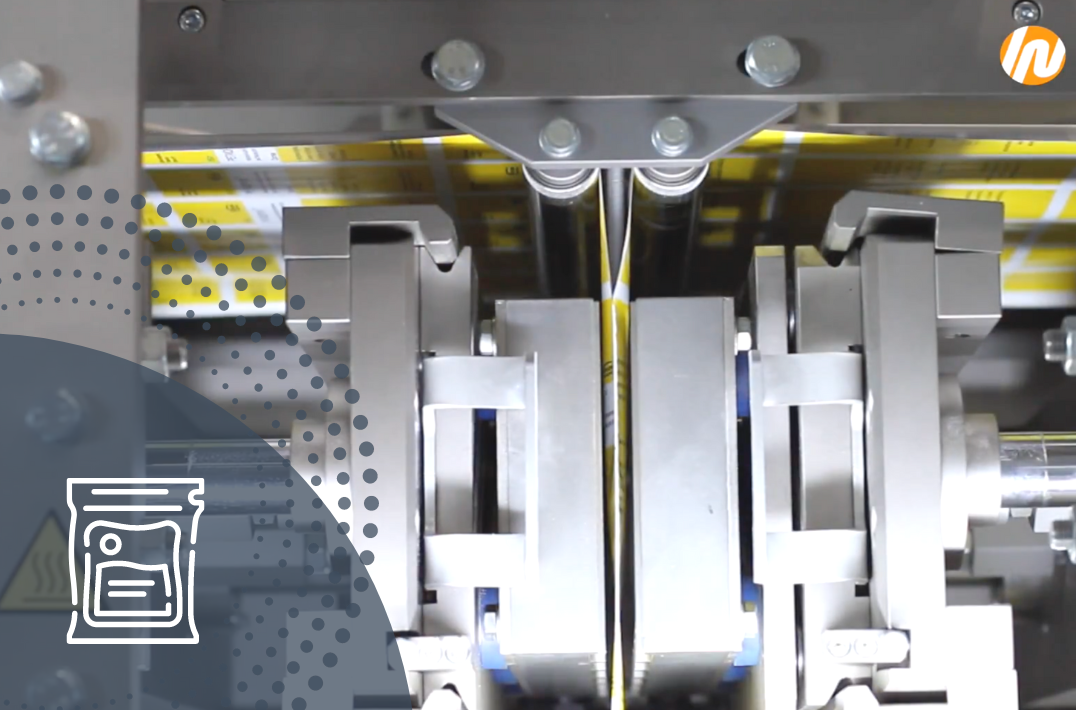

One of the ideal types of packaging for these dynamics is flexible packaging. For this purpose, one of the most common formats is the sachet, which is packaged in vertical packaging machines.

Sachet, the most popular single-dose packaging

Sachet packaging is always a good option. It is a multi-purpose sachet for a wide variety of products: solids, liquids, pasty, granular or powdered. In addition, its machinery can be adapted to comply with all sanitary regulations for packaging in more specific sectors such as dairy, pharmaceutical, food, cosmetic and nutritional.

The sachet is a four-seal sachet that offers maximum safety to prevent product leakage. Also, as it is a two-sided square sachet, it makes it possible to make attractive products in terms of graphic design, since it is possible to print and express the qualities of the brand and the product itself.

On the other hand, it is an easy-to-store package, which allows easy grouping for later cartoning.

Another factor in the popularity of sachet packaging is its ease of transport, because apart from its small size, it is a very light package. For all the above reasons, the consumer finds no impediment in carrying it with him in his daily life and consuming it whenever he sees fit. Some examples could be a medicine in single-dose format or a sachet of sugar.

Reasons for packaging sachets in vertical machines

1. One of the main reasons for packaging products in sachets in vertical packaging machinery is that it takes up less space and thus in the same area that a horizontal packaging machine would occupy, several vertical packaging machines could be placed.

2. Considering the above point, compared to horizontal machines, productivity is much higher considering the ratio of sachet units produced per m2.

3. Another reason for choosing vertical packaging machinery is that it allows the addition of secondary packaging machinery such as a cartoner, flow pack, stabilo, etc. to offer a total packaging solution completing the whole process.

All the arguments mentioned above are very interesting when evaluating which type of machinery to choose for packaging in sachet format. According to the data shown, vertical packaging machinery is a very good option.

Related posts:

Stick pack, environmentally friendly packaging

The world of packaging is very wide, but if we focus on flexible single-dose packaging, we find a...

4 solutions for packaging in single-dose stick packs

In the world of packaging there are many types of packaging, and the world of single-dose packaging...

Vertical machinery for packaging sachets

In the packaging industry there is a wide variety of formats for single-dose packaging.One of the...